Climate Protection and Energy Efficiency

With the Paris Climate Agreement, the international community committed to limiting global warming to less than two degrees Celsius above the pre-industrial level. At the Climate Change Conference in Glasgow in November 2021, this ambition was for the first time backed up with concrete reduction requirements for greenhouse gas emissions. By 2030, for example, global CO2 emissions must be cut by 45 % versus 2010, and net-zero emissions must be achieved by 2050. Meanwhile, in Germany, the “Climate Protection Plan 2050” currently sets out the interim goal of cutting greenhouse gas emissions by at least 55 % compared with the base year of 1990 by 2030. Industry is expected to contribute to this with a reduction of between 49 % and 51 %.

As of this year, LANXESS has joined the growing list of companies that have set themselves science-based targets to limit global warming to 1.5 degrees Celsius. The validation of our commitment by the Science Based Targets initiative (SBTi) indicates that we are on the right track.

Since it was founded, LANXESS has made substantial progress towards its goal of becoming more environmentally friendly. Between 2004 and 2018, we halved our greenhouse gas emissions from around 6.5 million metric tons of CO2e to about 3.2 million tons.

"With our 'Climate Neutral 2040' initiative, we are addressing one of the greatest challenges facing society - climate change."

Stephan Caspers,

Global Environmental Sustainability, LANXESS

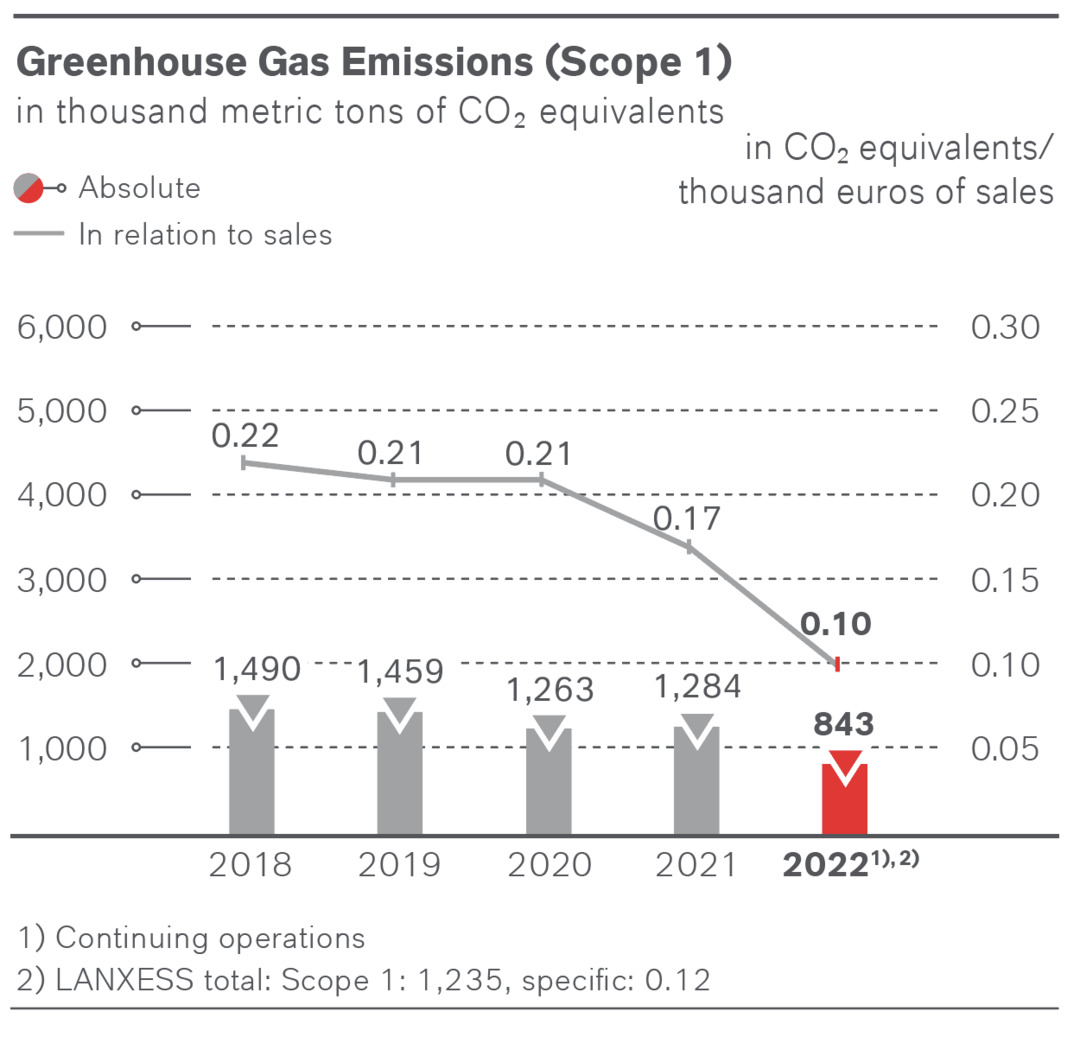

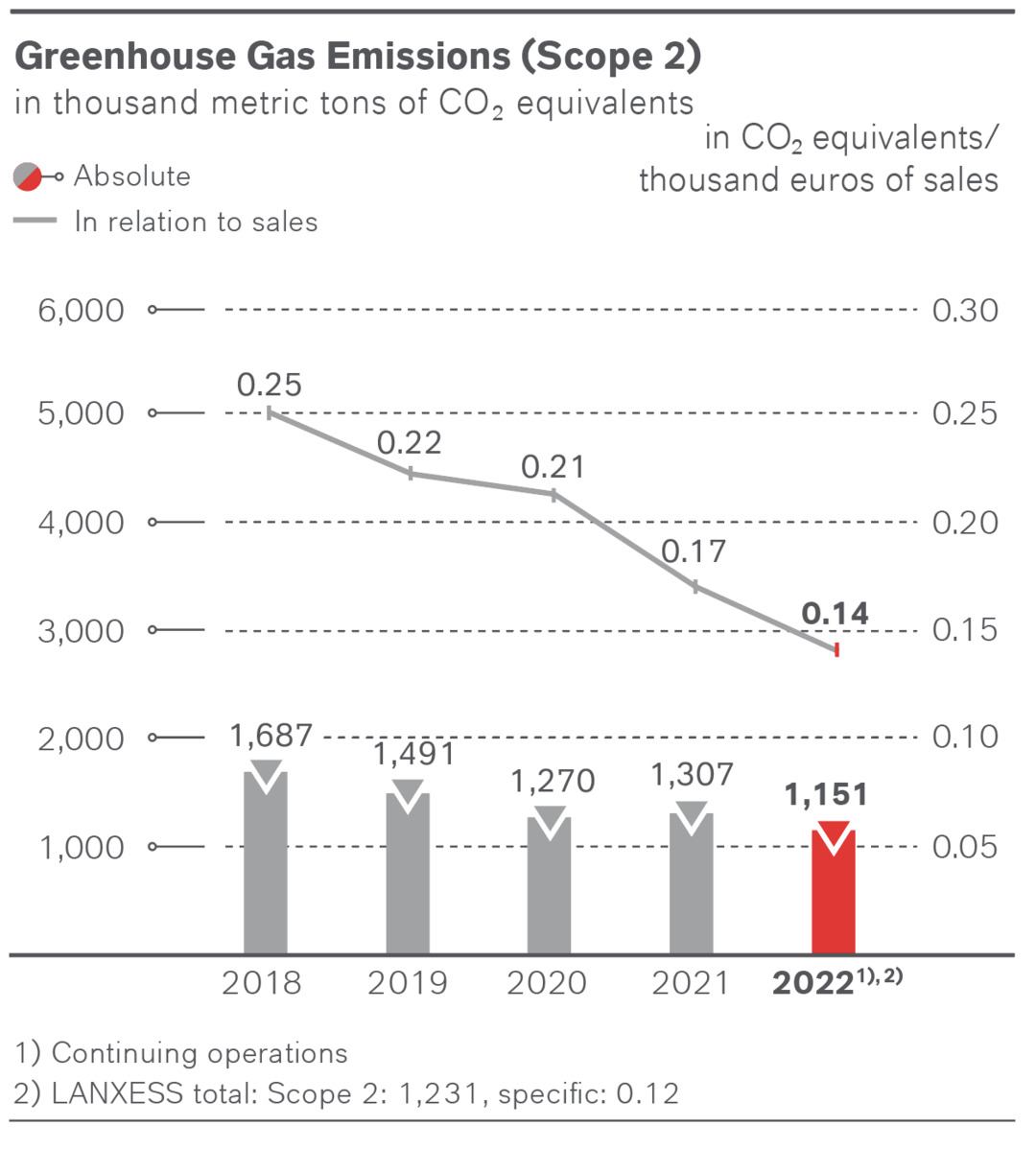

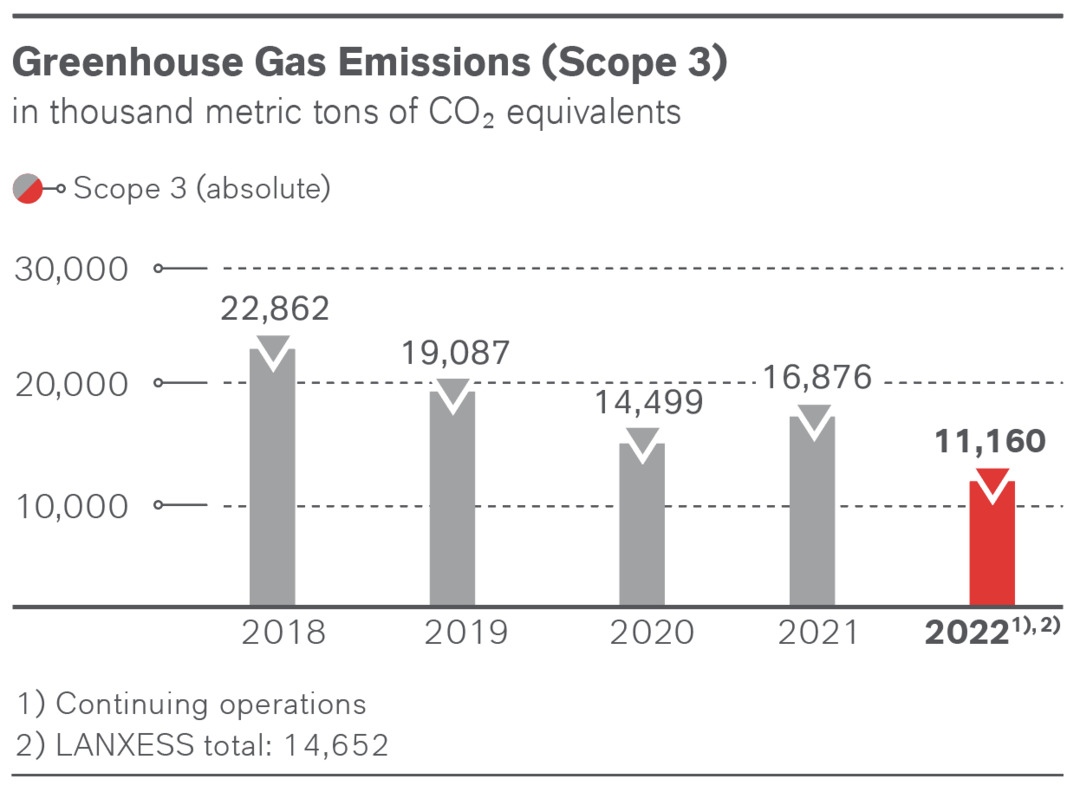

In light of this, it was therefore time to set new, ambitious medium and long-term targets and thus fulfill our responsibility as a global specialty chemicals company: LANXESS is to be climate neutral in terms of our Scope 1 and 2 emissions by 2040. By 2030, we aim to reduce the greenhouse gas emissions achieved in 2018 by more than half to around 1.3 million metric tons of CO2e. We will thus have achieved an 80 % reduction compared to the emissions when LANXESS was founded. To measure our climate-relevant emissions, we collect data on emissions of greenhouse gases defined in the Kyoto Protocol and calculate their greenhouse effect in comparison to carbon dioxide. We include emissions from our own production (Scope 1) and from external energy sources (Scope 2) in the calculation. 2022, LANXESS set a target for indirect emissions from the upstream and downstream supply chain (Scope 3) for the first time. The Group intends to make the entire supply chain climate-neutral by 2050.

Our journey to climate neutrality

- We drastically reduce emissions from internal sources.

- We reduce our specific energy requirement.

- We purchase very low-emission or climate-neutral energy.

1. Launch climate protection projects (medium-term target):

Over the next few years, several measures will significantly lower greenhouse gases.

For example, we are switching the energy supply in Jhagadia to a mix of biomass and solar power. This is expected to cut our CO2e emissions by a further 150,000 metric tons from 2024. As of the reporting date, the percent of renewable energies at the Jhagadia site was 37%, while the Nagda site achieved around 88%. We already operate a highly efficient cogeneration plant entirely with biomass in Porto Feliz, Brazil. We are also planning to phase out the use of coal-based energy at our major production sites in Germany.

Through these projects and other measures, we want to decrease our CO2e emissions to 2.3 million metric tons by 2025.

2. Break the link between emissions and growth (long-term target):

LANXESS is growing. But despite increasing production, emissions of greenhouse gases in our individual business units are set to shrink. In addition to technological efficiency, changes to governance instruments also play a significant role, with the impact on the company’s carbon footprint becoming an investment criterion for organic growth and acquisitions. This gives business units that achieve better than average reductions in greenhouse gas emissions a direct financial advantage. In 2020, the Board of Management and the Supervisory Board also decided that the reduction in CO2e will be used as an assessment criterion for the compensation system for managers and the Board of Management in the future.

3. Strengthen process and technological innovations (long-term target):

We are revising many of our existing production processes in order to go climate neutral by 2040. For example, we will continue to improve our composite structures, e.g. when it comes to heat exchange between plants and air purification. However, other procedures must first be developed on a large industrial scale. We will therefore focus our research activities more closely on climate-neutral process and technological innovation.

By implementing the above measures, we want to decrease our annual emissions to less than 300,000 metric tons by 2040. We plan to neutralize the remaining emissions via appropriate offsetting measures. In this way, we will not only make a significant contribution to climate protection in the years to come but also become an even more sustainable partner for our customers.

“Net Zero Value Chain” program: Clear strategy to lower indirect emissions

In 2022, LANXESS also developed a clear strategy to lower indirect emissions and launched the Net Zero Value Chain program. This aims to make the entire LANXESS supply chain climate-neutral. The indirect emissions in the upstream and downstream supply chain (Scope 3) are to be eliminated by 2050. The “Net Zero Value Chain” initiative is based on three pillars:

- Transition of raw materials purchasing to increasingly sustainable raw materials that are bio-based, originate from a recycling process or are produced with renewable energy.

- Greater consideration of carbon footprint when selecting means of transport.

- Expansion of our range of climate-neutral products and solutions with a low carbon footprint.

In the coming years and decades, climate change will have significant global consequences for companies’ business activities. This year, LANXESS therefore continued to work on an extensive risk analysis, based on three climate categories. We perform this scenario analysis globally for all locations and assess the risks that could arise in the short, medium and long terms.

Uncertainty over emissions trading

In Europe, 14 of our plants and sites are subject to European emissions trading. Trading with CO2 emissions rights, known as certificates, is intended to reduce emissions of the environmentally harmful gas CO2 costeffectively. Because all of our plants covered by emissions trading are state-of-the-art and compete at the international level, we expect to receive enough certificates from free allocation to cover the expected CO2 emissions by the end of the third trading period in 2030. At present, however, we cannot precisely estimate the effects of changes to the EU emissions trading system planned under the Green Deal.

Since 2021, the introduction of the Fuel Emissions Trading Act (n-ETS) has resulted in additional costs, which suppliers include in the natural gas price. We cannot yet precisely estimate further costs due to the Scope expansion planned from 2023.

In 2022, our absolute Scope 1 emissions were significantly lower than the previous year’s level, among other things this is due to the change in our portfolio. Moreover, the transition from coal to biomass at our Indian sites continues apace and is making a major contribution to the reduction of the CO2 figures. This is countered by the full-year consolidation of the sites from the acquisitions of Emerald Kalama Chemical and Theseo, which were only included pro rata in 2021. Because of our altered portfolio, the transition to biomass and increased sales, the specific Scope 1 emissions also decreased year-on-year.

For continuing operations, Scope 2 emissions are also significantly below the previous year’s level. This development is based mainly on the deconsolidation of the HPM business unit, but also a lower production volume.

The specific figure continues to decline due to the portfolio change and the increased sales.

A high level of energy efficiency improves not just our emissions footprint, but also our cost position, thus ultimately making LANXESS more competitive. Our global energy management promotes projects to increase energy efficiency in our plants. In each business unit, energy officers ensure communication and the ongoing improvement of energy-related performance. Technical experts from the central departments help the local teams to identify and implement effective projects to increase efficiency.

With this target, we have taken part in the Energy Efficiency Networks Initiative, established by the German federal government and leading industry associations, with several German sites since 2017. For example, our Mannheim site is currently participating in the ChePap 2 network, the Bitterfeld site in the Bitterfeld-Wolfen 2.0 network.

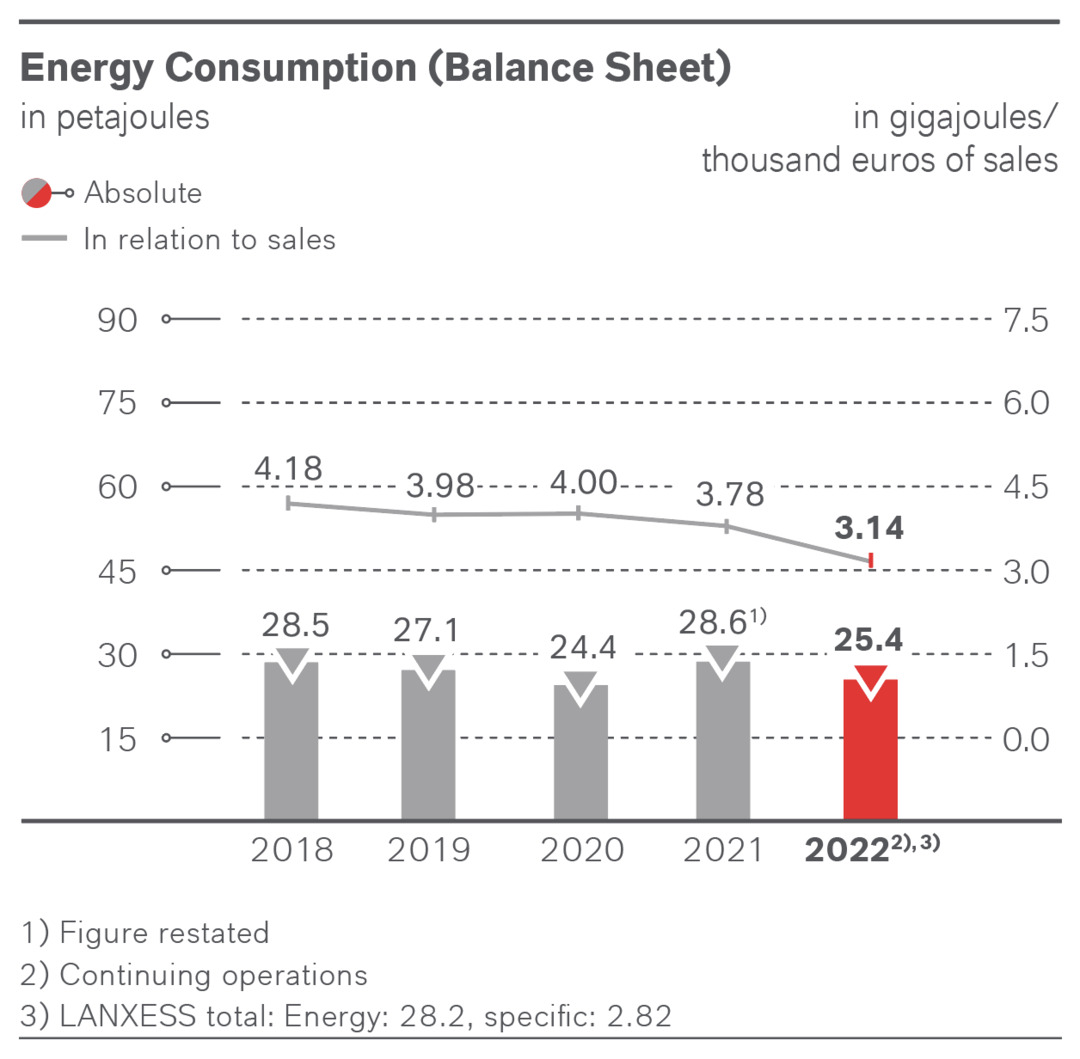

Both our absolute and our specific energy consumption declined in 2022. Besides the effect of the altered port-folio, lower production volumes and efficiency measures also helped to reduce energy consumption.

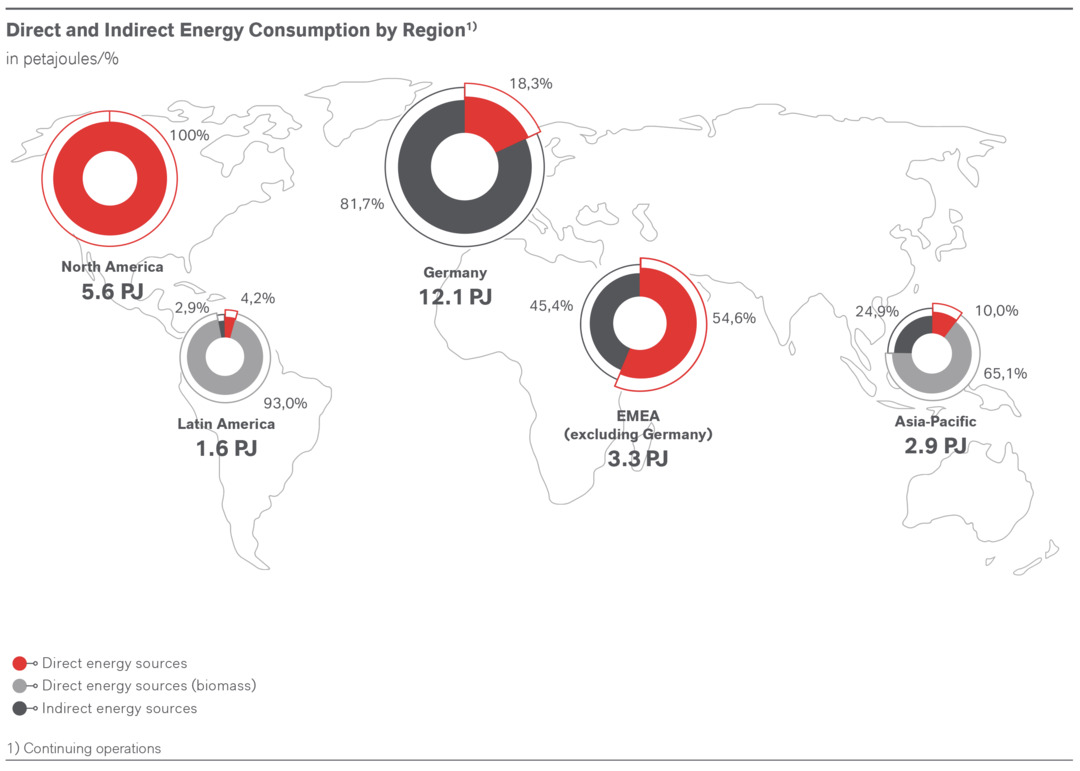

An analysis of energy consumption by region shows stark regional differences both in the amount of energy and the types of energy source.

We are particularly endeavoring to transition from road transport to intermodal transport options. In this context, we are currently making targeted investments in digital solutions that tell us the status of ship transports early on so that we can plan the subsequent land transport with means of transport with the lowest possible emissions in a forward-looking manner. Furthermore, we plan to make increasing use of comparatively low-emission combined-transport options, where most of the distance involved is covered by train, barge or sea vessel, thus keeping initial and final journeys by road to an absolute minimum. Europe in particular has a strong infrastructure for these types of transportation. However, increased use of rail means that combined transport is even an option for long-distance connections to China.

To transport our rail freight in Germany, we continue to use the TÜV SÜD-tested Eco-Plus service of the logistics company DB Cargo. The power required for transportation is obtained from regenerative energy sources. As a result, we can reduce our CO2 emissions in national rail transportation by approximately 80 % compared with conventional options.

Further information on our climate strategy can be found in the “Climate” Background Paper.