Safe and Sustainable Sites

LANXESS operates a total of 57 production sites and has a presence in 18 countries (investments ≥ 50%, as of December 31, 2022). Our wide range of products requires the use of many different chemical and technical processes. Uniform standards for planning, building and operating plants ensure a high level of process, plant and occupational safety.

Handling chemical substances and working with technical equipment involves health and safety risks. We identify these risks and potential threats systematically worldwide – for new and existing plants – and minimize them by implementing defined preventive and protective measures. Experts examine implementation of LANXESS guidelines and local regulations for safe operation of our plants on-site via targeted spot checks in audits whose frequency is geared toward the respective risk profile.

We use an electronic reporting system (Incident Reporting System – IRS) to record accidents and events worldwide in line with uniform regulations. In 2022, the new Intelex Incident Management System replaced its predecessor IRS (Incident Reporting System). By the way of digitalization, the new, more agile and flexible system provides a platform for greater data and process safety and better functionality on mobile devices. Injuries, transportation accidents, near-accidents, environmental incidents, instances of damage and security-relevant incidents such as theft are documented. Each event is carefully analyzed in order to draw conclusions as to how we can avoid similar incidents in the future. All measures count toward our goal of continuously reducing the number of events. The number of major incidents in 2022 was in single digits.

We are continuing the systematic digitalization of production, including by digitizing our paper-based operational management and maintenance checklists. Tablets are now in use that are directly connected to the central IT systems at LANXESS and enable realtime access to data. The solution includes the end-toend integration of digital data processing in the work process and ensures that data are archived correctly and automatically. Thanks to the clear, complete data, we can now directly derive necessary measures and implement them immediately. This not only increases work efficiency in production and maintenance, but also avoids duplication of work.

A centrally organized management system at LANXESS provides for the necessary global management structures in all business processes in order to ensure responsible business activities. Globally, we base our actions on the international standards ISO 9001 and ISO 14001 for quality and environmental management and ISO 50001 for energy management.

Confirmation of compliance with the standards ISO 9001 and ISO 14001 is provided in a global matrix certificate. This brings a whole range of benefits:

- high degree of standardization of processes

- uniform in-house guidelines and instructions

- transparent, efficient, and effective processes and controls

- considerably reduced external expense for the maintenance and optimization of the management system, for the integration of additional management systems (e.g. ISO 50001, sustainability standards), and for the integration of new sites or business units.

We ensure that progress in integrating new sites into our management system and its performance are regularly reviewed worldwide by independent external experts. In 2022, we successfully passed the recertification audit in accordance with the standards ISO 9001:2015 and 14001:2015 and the recertification audit in accordance with ISO 50001:2018.

With a global hazardous-goods and transport-safety management system, we ensure that we minimize or entirely avoid hazards. We coordinate, monitor and review implementation of relevant hazardous-goods and transport-safety regulations as well as in-house regulations centrally in a department that is specifically responsible for this.

Central classification of our products in line with international, regional and local hazardous-goods regulations ensures that applicable laws are interpreted uniformly while taking regional and local aspects into account. Classification determines such things as the type of containment (packaging and tanks), marking and labeling, the permitted modes of transport and transportation routes as well as measures that operational staff must take if a transportation event occurs. The corresponding classification data is stored in the central safety-data system for chemicals at LANXESS. In connection with the introduction of the new enterprise resource planning system, more than 11,000 products and raw materials of LANXESS Deutschland, Saltigo, LANXESS Organometallics and Theseo were migrated to the central system in 2022.

We regard preservation of natural resources – for example by using raw materials and energy as efficiently as possible – and identification of further potential for reducing emissions and waste as an ongoing task in the context of our environmental responsibility and expertise. We equip all new production sites in accordance with the state of the art, taking environmental standards and local requirements into account.

We are focused, firstly, on responsible use of water as a resource, which includes both water consumption and water quality. Secondly, we endeavor to fulfill our ecological responsibility with regard to waste. The clear focus is compliance with all legal requirements. In line with circular economy, LANXESS strives to enforce the waste hierarchy – prevention, reuse, disposal – around the world.

Sparing use of water

Handling scarce water resources in a conscious and careful manner is an investment in the future. In order to break the link between our growth and water consumption and potential stresses from wastewater discharge, we have set ambitious targets at Group level. We are aiming for an annual reduction of both specific water consumption and specific total organic carbon (TOC) in wastewater flows by 2 %.

LANXESS Water Program

As a chemicals company, we rely on water for our production. We use it mainly for cooling (80 %), as an input material in chemical processes (18 %) or in the form of steam (2 %). In addition, rivers are an important transportation tool, particularly for our networked sites in Germany.

We aim to avoid hazardous as well as non-hazardous waste as far as possible and to break the link between our business growth and waste production. Rigorous materialflow management from use of raw materials to product finishing is aimed at ensuring that we use resources as efficiently as possible and minimize our waste volumes.

Our business units and sites strive to increase efficiency and are working constantly on various research projects for the prevention, reduction and recycling of waste. In turn, our networked sites enable us to re-use many waste and secondary flows as a raw material directly in neighboring plants – both our own as well as those of other chemicals companies – to create closed loops and thus avoid the generation of waste. In addition, we are working to achieve the targets defined in the international program “Operation Clean Sweep” (OCS) of the Society of the Plastics Industry. OCS aims to prevent plastic particles or pellets from entering the marine environment and having an undesired impact. By joining in 2016, we made a commitment to train employees in this area, to implement measures to prevent the release of pellets at our facilities and to require our business partners to also take active steps to prevent pellet emissions.

In 2022, LANXESS ramped up its activities with regard to waste. Various working groups conducted potential and market analyses to look at new on-site and off-site recycling options, partnerships for innovative chemical recycling processes or the further standardization of waste reporting. The goal is to increase the circularity of waste streams.

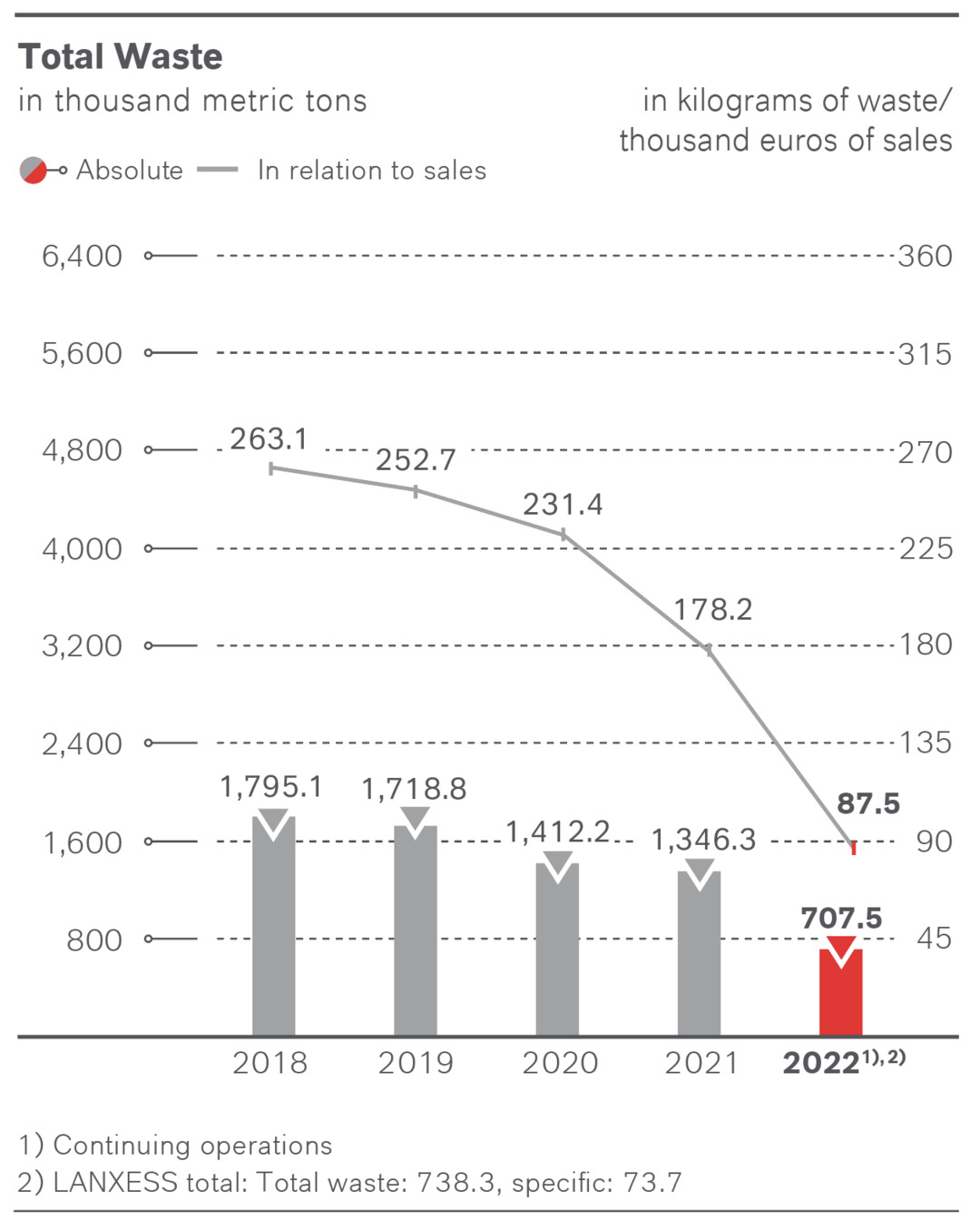

The amount of waste generated has decreased significantly compared to the previous year. This is due on the one hand to the portfolio change and on the other hand to an adjusted declaration of aqueous waste streams at our site in El Dorado, U.S., on the basis of updated reporting standards. From the year 2022, the site’s slightly polluted wastewater is reported as wastewater. The remaining wastewater still accounts for the biggest share of our waste.

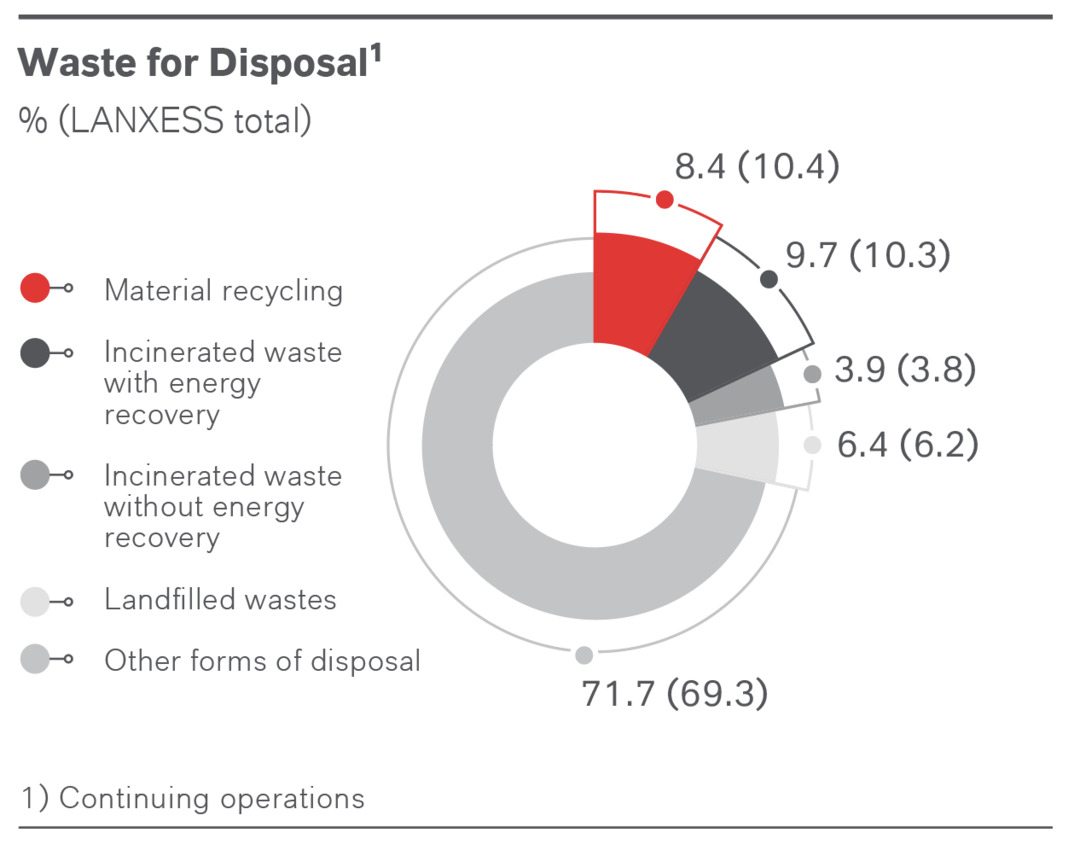

We group waste into five categories, each divided into hazardous and non-hazardous waste. The chart shows each category’s share (in %) of total waste.

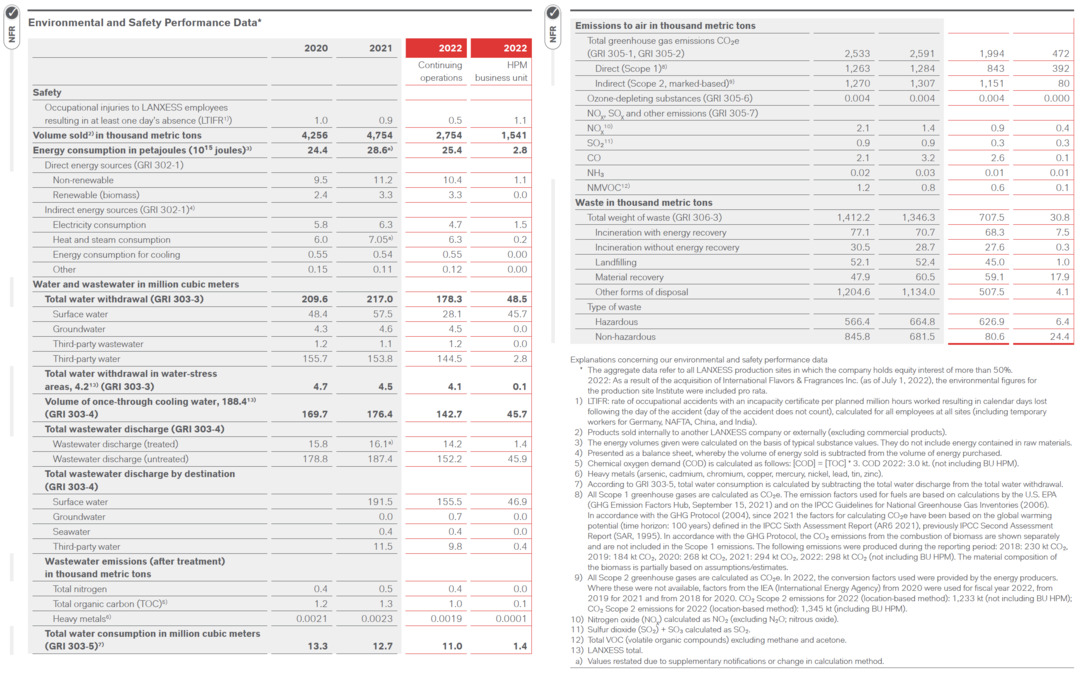

To record key data on safety and environmental protection systematically worldwide, we use an electronic data-entry system.

This enables us to calculate a wide range of HSE performance data for each business unit and site worldwide, which is used as a valid data pool for strategic decisions as well as internal and external reporting. In addition, it maps the progress that we make with our global sustainability targets. Data is gathered only at production sites where we have investment of over 50 %. Due to the deconsolidation of the HPM business unit, we are disclosing this data separately.

PricewaterhouseCoopers GmbH Wirtschaftsprüfungsgesellschaft audited our environmental and safety performance data and the requisite data-gathering processes with limited assurance for fiscal year 2022.

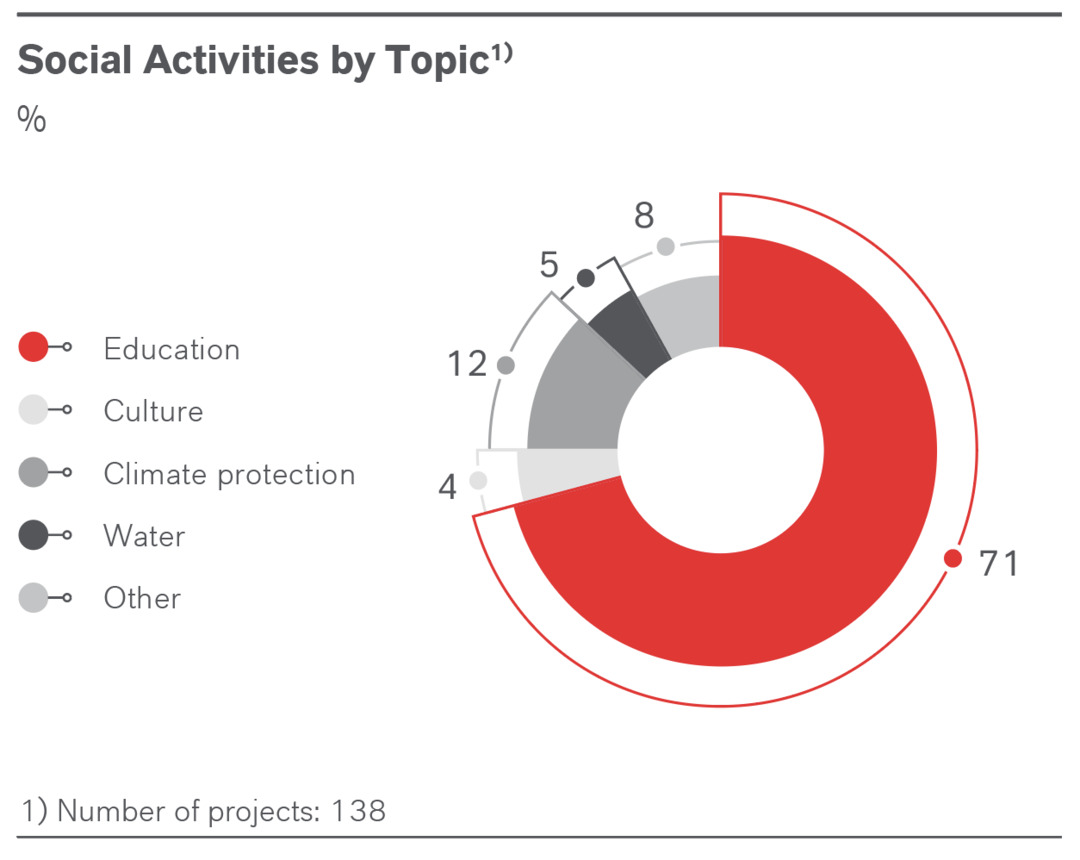

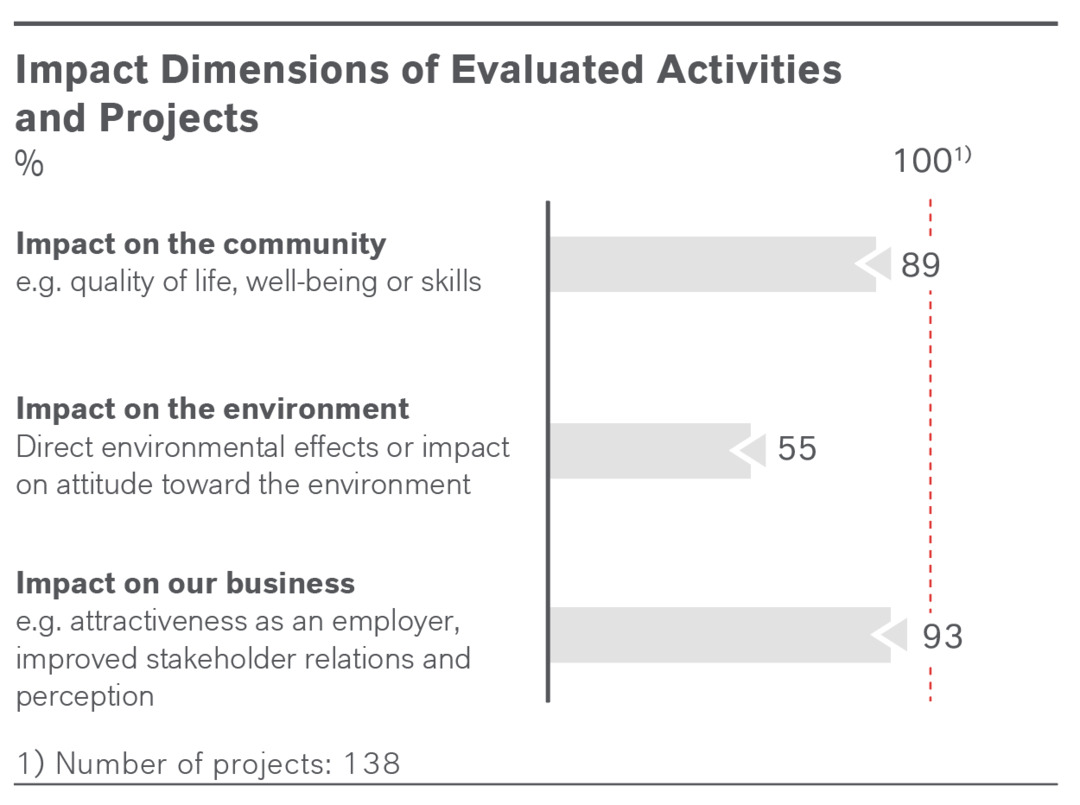

Our understanding of sustainable sites also includes being a strong and reliable partner for the people locally and in the respective region and taking responsibility for development of the social environment. Our social commitment is based on our corporate expertise and objectives and focused on education, climate protection, water and culture. Our goals in all these areas are identical:

- Mobilizing resources and people for social commitment

- Achieving positive impacts on the company, the environment and society

As a company, we aim to play a positive part in improving living conditions, education, training and equal opportunities as well as health and safety. In addition, we are working to attract talented persons, engage in extensive dialog with our stakeholders, have a positive influence on employee motivation and constantly improve our reputation.

We provided around €1.3 million globally for our projects in 2022 (previous year: around €1.5 million). The regional focal points of our activities in the reporting year were the EMEA and USMCA regions.

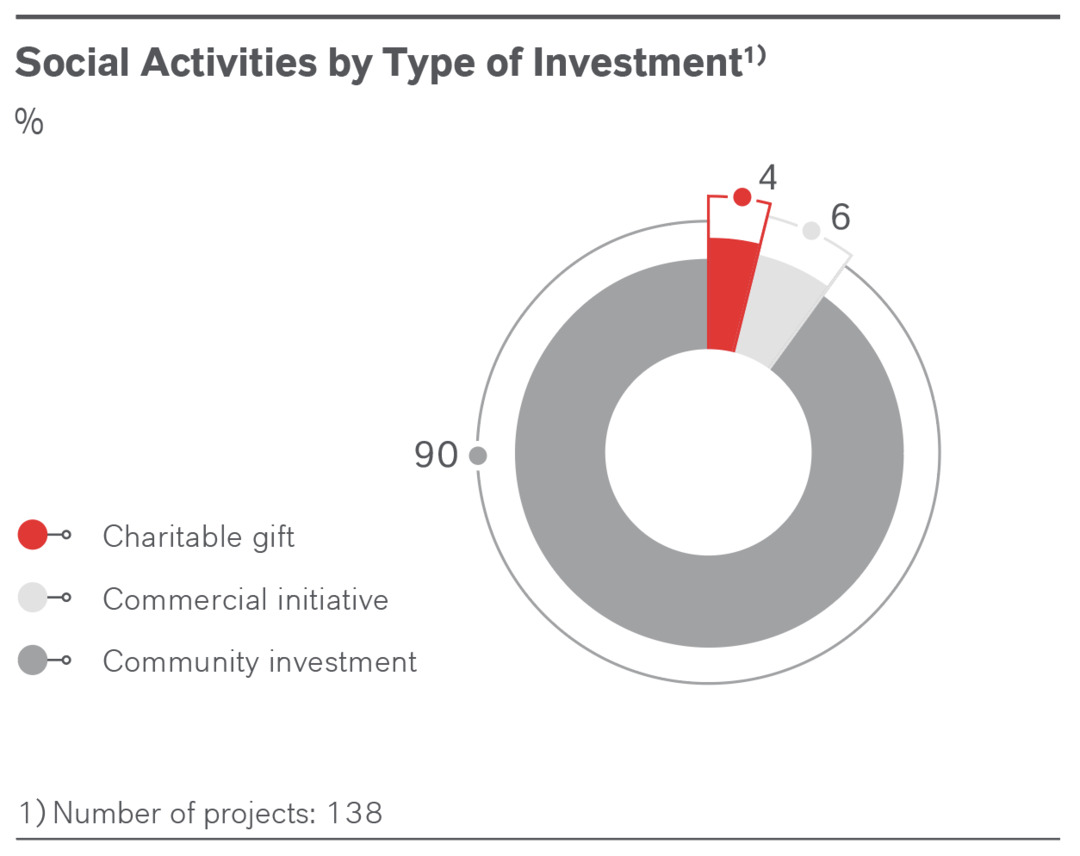

In decisions on social commitment, we assess our projects according to whether they pursue purely charitable ends (“charitable gift”), whether we are investing in the social environment of our sites (“community investment”) or whether we are investing in corporate objectives such as image, sales and income while also generating social value (“commercial initiative”).

Commitment to education, climate protection, water and culture

Under the LANXESS education initiative, starting in 2008, we have initiated more than 500 projects at our sites worldwide to get young people interested in the natural sciences at an early age. In 2022, we supported a preparatory seminar for 20 schoolchildren from North Rhine-Westphalia, who had qualified to take part in the 54th International Chemistry Olympiad in China, with a sum of €10,000. In Brazil, we implemented the “Formare 2022” program together with the Iochpe Foundation, which prepares young people from low-income backgrounds for the world of work and helps them look for their first job. The program is conducted in partnership with companies that provide their employees as volunteer educators. For example, ten young people from Porto Feliz were chosen to be prepared for vocational training for the role of “Production Operator in the Chemical Industry.”

In another project, LANXESS helped municipal schools in Nagda, India, to set up digital classrooms with interactive e-learning tool and a digital library. The schoolchildren also have access to a chemistry lab complete with instruments. In Japan, we strove to educate schoolchildren about climate change and its impact. Our newly developed “Climate Class and Science Experiment Workshop” program started in 2022, providing opportunities to learn about the environment and the fight against climate change. In the reporting year, we offered three workshop for children in grades one through six. In Brazil, the “Juntos pelo clima 2022/Together for the Climate 2022” project saw elementary schoolers learn about ecological challenges and how they can help to solve them on an environmental activity trail.

In 2022, LANXESS India also assisted the local community in Jhagadia, in the state of Gujarat, and the surrounding villages with the installation of solar-powered streetlights. They not only illuminate the villages but also help to make the roads safer.

In order to meet the demand for water in the arid Nagda region in Madhya Pradesh, India, our Indian company implemented a rainwater-collection project aimed at raising the water table. A similar project was also carried out in Jhagadia. Moreover, the eighth “Clean Water for Better Life” research competition was held for students in China.

As part of our cultural commitment, we have been sponsoring the international literature festival lit.Cologne as a lead partner since 2010 and the Kölner Philharmonie for several years. The Ozawa International Chamber Music Academy in Japan, which we have likewise supported for more than twelve years, gives talented young musicians from all over Asia the opportunity of first-class musical training.

Ukraine war: LANXESS donates €200,000

In light of the dramatic events in Ukraine, LANXESS has supported humanitarian aid. In the reporting year, the company donated €200,000 to “Aktion Deutschland Hilft,” a grouping of more than 20 aid organizations. The alliance is currently active in Ukraine and its neighboring countries. It has links to local organizations and supports families fleeing the war – in Ukraine and at the stops on their journey.