Sustainable Products

We see the constant improvement of product safety, which is enshrined as a core aspect of our corporate policy and in the Group-wide management system, as part of our product responsibility. We have undertaken to avoid risks for humans and the environment across all phases of the product lifecycle through safe research, manufacturing, storage, logistics, use and disposal.

With regard to the safety of our products, our ambitions exceed the legal requirements in many areas. Examples of this include the creation of safety data sheets even for nonhazardous substances and our roadmap for a sustainable product portfolio. Our “Product Safety Management at LANXESS” guideline stipulates how product responsibility is to be exercised throughout the Group and ensures collaboration between all of the parties involved. The Production, Technology, Safety & Environment (PTSE) Group function ensures that laws and regulations are complied with, resulting obligations and preventive measures are derived and their effective implementation monitored.

We classify and label hazardous products (substances and mixtures) in packaged form in accordance with hazardous substances legislation before they are used or brought to market. We regularly adapt our electronic safety data system to take account of new features in GHS (Globally Harmonized System of Classification and Labeling of Chemicals) legislation in the different countries. We thus ensure that risks for humans and the environment are avoided in transport, storage, use and disposal.

Complying with global chemicals control regulations across the whole value chain is an essential prerequisite for the saleability of our chemicals and chemical products. We go to great effort to ensure comprehensive compliance both for our own products and together with our partners for their products, which are our raw materials, for example. Particularly in the case of consumer applications, it is extremely important to us that our products meet high national and international standards, certificates, and quality seals.

Many plasticizers with phthalates are considered to be extremely hazardous to health. Many of these are severely restricted or prohibited in the EU by REACH or other regulations. The reason: they can endanger procreation and unborn children. US authorities also ban these substances. LANXESS produces only phthalate-free plasticizers. One of these products is Mesamoll. It is used, for example, in water beds, bouncy castles and water balls. One advantage of Mesamoll is that it gels well, and can therefore be processed at lower temperatures, and in a shorter time than other plasticizers.

Materials that we produce in the EU or import into the EU in quantities of more than one metric ton per year are registered, listed and evaluated in accordance with the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) Regulation. We conduct workshops for our REACH officers in the business units at least twice a year in order to present new developments, promote understanding of the importance of product responsibility and guarantee legal conduct. The REACH requirements have been continuously updated since 2007, so it is necessary to regularly review and revise the registration dossiers. In this context, we support the voluntary Action Plan of the European Chemical Industry Council CEFIC (Conseil Européen des Fédérations de l’Industrie Chimique) and have undertaken to review and – if necessary – update our REACH registration dossiers by 2026 at the latest.

The safe use of our products, along both our own and the downstream value chains, is another essential part of our product responsibility. Our business units help their customers to use our products safely and in an eco-friendly way by way of training and advice and shed light on the risks associated with use. In our electronic safety data system, we provide our customers with safety data sheets and extended safety data sheets for all substances handled regularly – including intermediates.In line with societal trends and needs, we aim to constantly improve the sustainability performance of our product portfolio, to identify critical substances in products and to substitute them or develop safe alternatives.

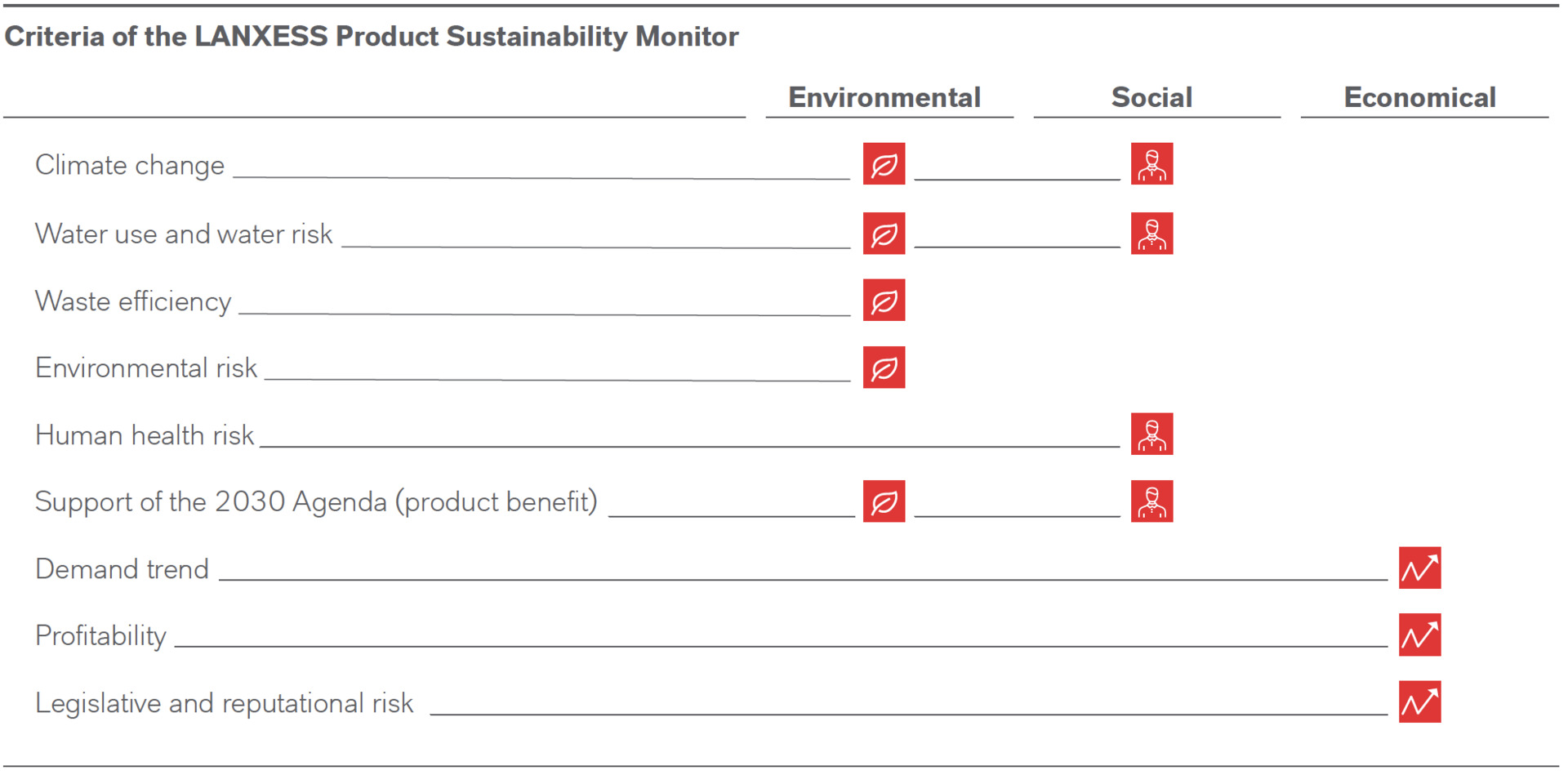

For the management and long-term development of our product portfolio, we follow an approach with three perspectives. This is based on the LANXESS Product Sustainability Monitor. Using this analytical tool, we identify products that are produced in a particularly sustainable manner as well as products where we see potential for improvement, and have been increasing the sustainability performance of our portfolio for years.

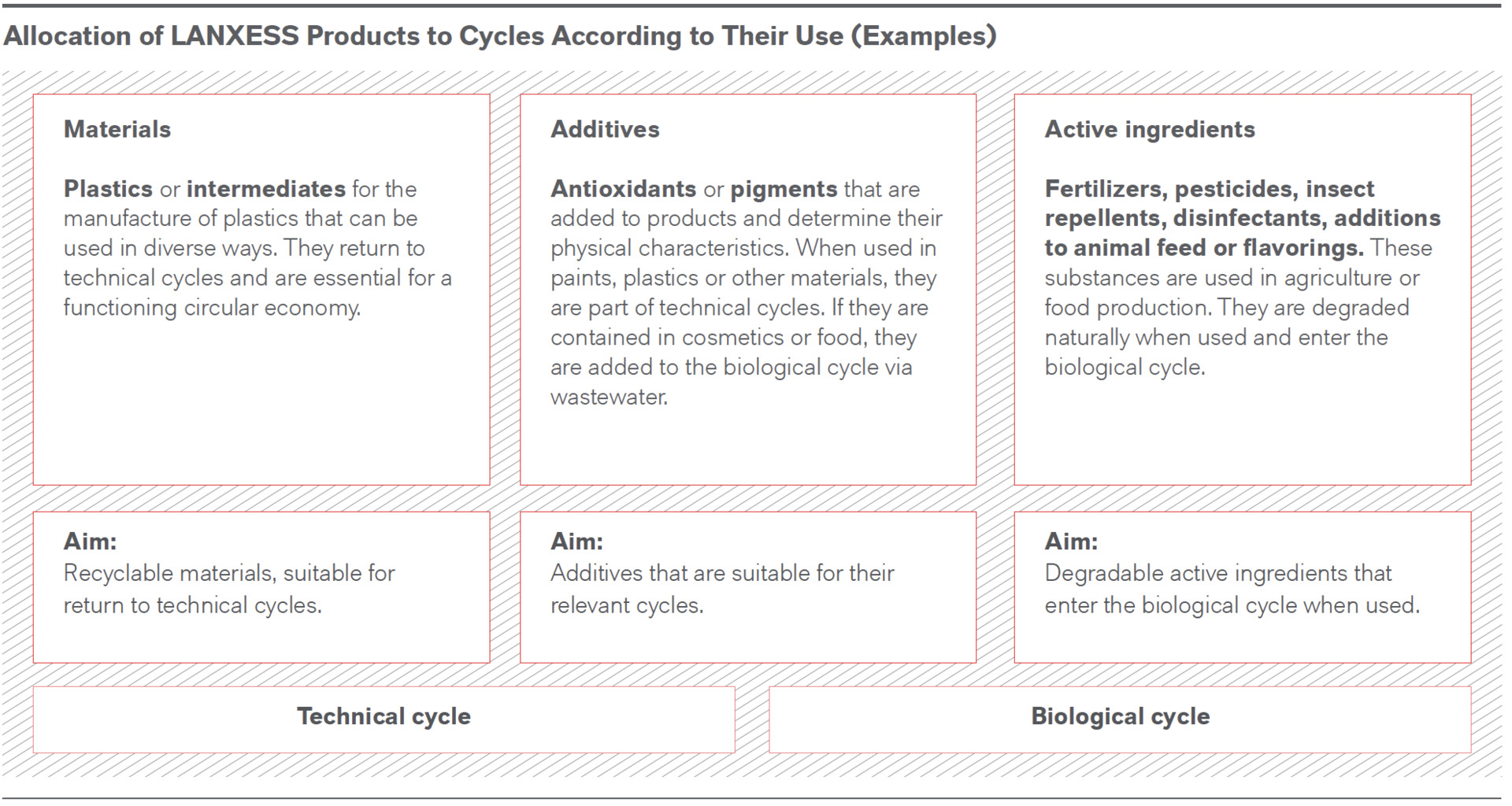

The second significant perspective is the product carbon footprint (PCF) and the circular potential of our products. Here, it is important to understand and account for the upstream value chain as well as our own production. The aim is to continuously reduce our products’ influence on the climate, to use sustainable raw materials and to ensure that our products can be recycled.

As a third perspective, we look at the benefit of our products in their application. A sustainable world needs not only sustainably manufactured products but also solutions for new concepts such as in the areas of climate protection or circular economy. For example, additives make a significant contribution to extending the useful life of products or enabling materials to be recycled.

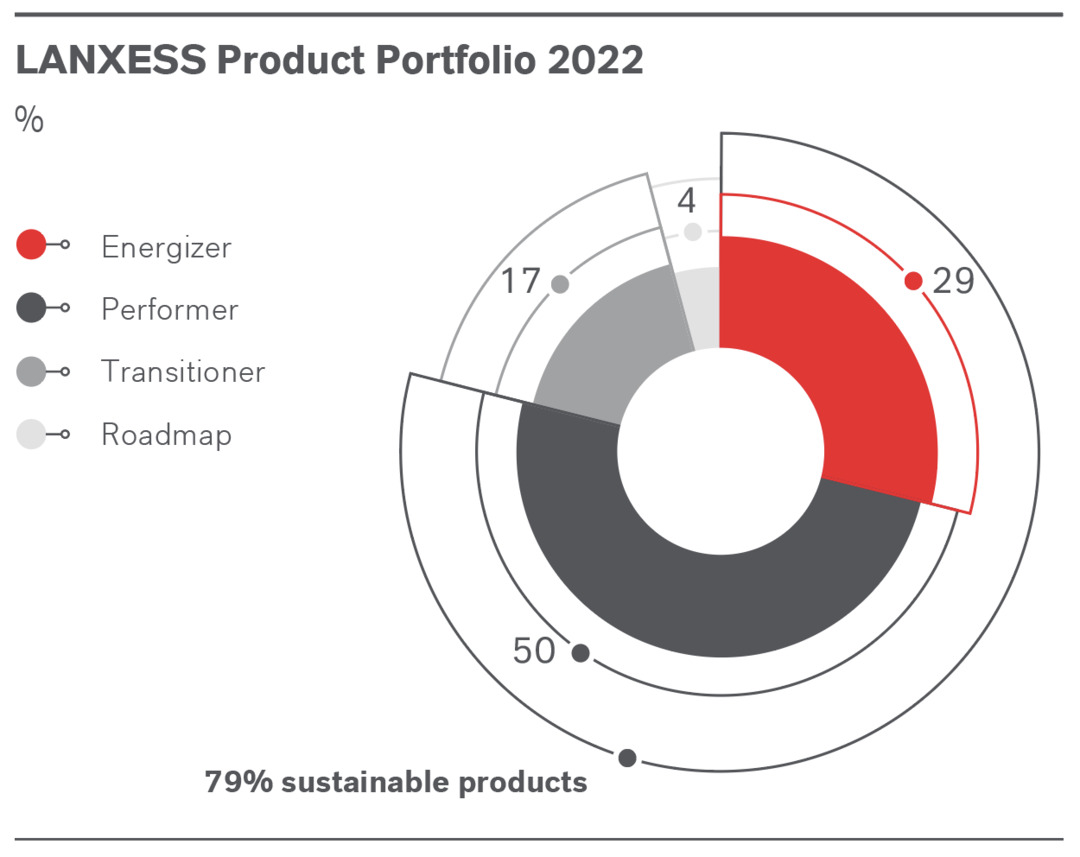

In the future, the EU taxonomy will be an additional, independent perspective. At present, for the chemical industry it concentrates chiefly on the identification of activities associated with particularly high carbon emissions, i.e. on high-volume basic chemicals and plastic products. In this respect, only a small portion of the LANXESS portfolio is relevant here.Using the LANXESS Product Sustainability Monitor, we divide our portfolio into four categories:

- Energizer: Products in this category offer outstanding sustainability performance. The fulfill our highest sustainability requirements in most criteria and haven no intrinsic properties that give cause for concern. Energizers are manufactured with a very low to low environmental impact. These products contribute to at least one SDG and are experiencing increasing demand.

- Performer: Products that are sustainable according to the current state of the art. The fulfill the present sustainability requirements or exceed them in many categories. Performers are manufactured with a low to medium environmental impact and have a benefit to society.

- Transitioner: Products that do not yet fulfill all LANXESS sustainability requirements. We monitor these products and actively steer them by way of improvement measures, for example to reduce their environmental impact and make these products more sustainable.

- Roadmap: This category covers products with serious sustainability concerns, namely chemical end products with more than 0.1% by mass of substances with the properties of substances of very high concern (SVHC). We manage these products in our roadmap process, in which we examine in particular whether critical substances in the respective chemical end products could be replaced with safe and sustainable alternatives.

We want to help transform the entire value creation system into a resource-efficient and climate-neutral society. On the road to climate-neutral and circular products, we are focusing on three partially overlapping action areas.

When selecting products, knowledge about the carbon footprint is becoming increasingly important – both for us and for our customers. Our aim is to continuously reduce the PCF and thus our products’ negative impact on the climate. In a cradle-to-gate assessment, the PCF results from:

- Emissions from our own processes (Scope 1)

- Emissions from purchased energy (Scope 2)

- Emissions from purchased goods, upstream transport and waste generation (Scope 3)

As a company, we can directly influence our Scope 1 and Scope 2 emissions in particular. With our strategy for climate neutrality in 2040, we have set ourselves ambitious targets in this area (see “Climate Action and Energy Efficiency”). Much more important for the PCF than the Scope 1 and Scope 2 emissions are often the Scope 3 emissions of purchased goods, i.e. our raw materials. In chemical production, they often account for more than 50% of the PCF. We are therefore placing a strategic focus on the purchase of sustainable raw materials with a reduced carbon footprint. The transformation away from conventional, often fossil-based raw materials towards renewable resources not only leads to a reduction in greenhouse gas emissions, but also makes our value chains less dependent on certain limited resources (see “Circular and Sustainable Sourcing”).

LANXESS products are sold almost exclusively to industrial customers. Only they or customers even further downstream use them to produce end products for a wide range of markets. For example, automotive suppliers use our high-performance plastics in components for lightweight automotive construction, which are ultimately built into vehicles by car manufacturers. Our chemical end products, which remain unchanged in the further value chain, are only processed into end products by our customers. With regard to completing cycles, this means that there are sometimes very long periods between production and the end of our products’ lifecycles. As a first step, we are therefore focusing on what we as a company can control: We are working to ensure the “recyclability” of all our products so that they are suitable for environmentally friendly recycling. In order to understand which “recyclability” requirements to impose on our products, it is important to analyze the function of our molecules in their final use and in which cycles (biological or technical) they circulate.A full picture of our product portfolio is obtained only when assessing the benefit and the positive environmental impact that our products have when used. Here, we prioritize solutions that contribute to climate protection or enable a circular economy.

Products that support climate protection are suitable for reducing greenhouse gas emissions and thus stopping or slowing climate change (climate mitigation). A second important group are products that support adaptations to climate change – i.e. help to cope with the negative consequences resulting from changes in the climate that have already materialized or are expected in the future (climate adaptation).

The biggest drivers of climate change are the generation of electricity and heat. The change from fossil fuels to renewable energy requires a large number of new solutions, especially for wind power, photovoltaics and the necessary storage of energy in the form of batteries or hydrogen. The transport sector and especially road traffic are other significant causes of climate change. Lightweight automotive construction with modern plastics harbors potential to considerably reduce fuel consumption in vehicles with combustion engines. In recent years, electric mobility has also become established as an important path to a sustainable future in road transport. Industry and the building sector are in third place when it comes to the emission of greenhouse gases. Electrification and insulation play a key role here. We address all these topics with our product portfolio.

A central element in the European Union’s Green Deal is the strategy for sustainable financing. It aims to channel financing flows into investments that support sustainable development in the future. In this context, a new classification system for economic activities – the EU taxonomy – is to help investors assess whether investments contribute to political targets and obligations such as the Paris Agreement on climate change at the same time as meeting specified environmental and social standards. To this end, the EU has defined six categories, or objectives:

1. Climate change mitigation

2. Climate change adaptation

3. Sustainable use of water

4. Transition to a circular economy

5. Pollution prevention and control

6. Protection and restoration of biodiversity and ecosystems

The relevance of an economic activity for one of these environmental objectives depends on how the activity influences the respective environmental objective.

In order to assess an economic activity, a two-step analysis must be performed with regard to eligibility and alignment. To determine alignment, each activity must be assessed as to whether it makes a substantial contribution to any given objective of the EU taxonomy while doing no significant harm (DNSH) to any of the other objectives.

Moreover, minimum safeguards for compliance with human rights including labor and consumer rights and in the fields of bribery and corruption prevention, taxation and fair competition must be guaranteed for each activity.

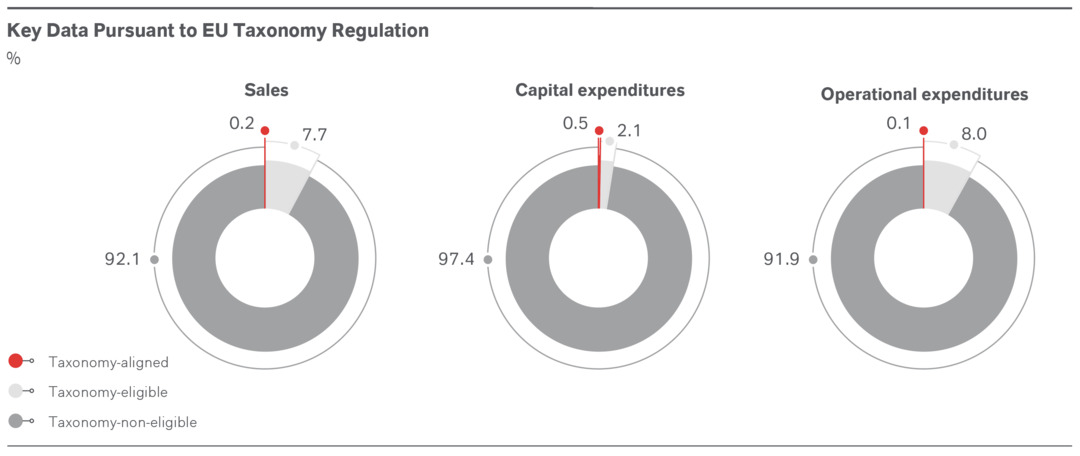

Companies that fall within the scope of the EU taxonomy must disclose the defined sales, capital expenditure (CapEx) and operating expenditure (OpEx) ratios for their share of taxonomy-eligible or taxonomy-aligned economic activities. These ratios must be itemized according to the respective taxonomy-eligible or taxonomy-aligned economic activity. The disclosures must specify the envi-ronmental objective to which this activity contributes and whether it is a transitional or enabling economic activity.

Taxonomy-eligible activities at LANXESS

With regard to the environmental objectives “climate change mitigation” and “climate change adaptation,” the Taxonomy Regulation covers activities of selected economic sectors that are currently responsible for a total amount of around 93% of European greenhouse gas (GHG) emissions. All of these activities are described as “taxonomy-eligible.” With regard to the “climate change mitigation” objective, the chemical industry is a “transformative industry” because, among other things, basic chemicals and plastics that are produced in very large quantities are labeled as transitional activities. This means that the activities make a relevant contribution to the EU’s GHG emissions and thus have relevant reduction potential. LANXESS – as a specialty chemicals company – is not focused on such products. Under the EU Taxonomy Regulation, all other activities that do not materially contribute to GHG emissions in the EU and accordingly are not defined in the Climate Delegated Act are currently labeled as “taxonomy-noneligible”. Criteria for the demonstration of “enabling activities” – i.e. activities that in turn enable third parties to make their own material positive contribution to climate change mitigation – have not yet been defined for the chemical industry.

Economic activities that LANXESS classifies as taxonomy-eligible:

- LANXESS produces high-quality plastics for a broad range of applications – from the automotive and electrical/electronics industries to water treatment. All of these products correspond to activity 3.17 “Manufacture of plastics in primary form” defined in Annexes I and II of the relevant Delegated Regulation. We have bundled the large majority of our plastics activities in the Engineering Materials segment.

- Adipic acid is a precursor that is in very high demand in the plastics industry, e.g. for polyamides or polyurethanes. At LANXESS, it is manufactured in the Advanced Intermediates segment. This product is allocated to activity 3.14 “Manufacture of organic basic chemicals” in the above Annexes. All other products described there are not manufactured by LANXESS.

Reportable ratios

Sales

LANXESS generated 8% of its external sales with products allocable to taxonomy-eligible activities. The remaining 92% of sales relate to products that are not included in the taxonomy’s activity categories. Compared to the previous year, the share has decreased significantly as the taxonomy-eligible sales from the High Performance Materials (HPM) business are no longer reported as continuing operations.

Capital expenditures and operational expenditures

We report the proportion of expenditures and expenses incurred in connection with the operation and expansion of our plants in order to manufacture taxonomy-eligible products as taxonomy-eligible capital expenditures and operational expenditures.

Capital expenditures

The share of taxonomy-eligible capital expenditures was 3%. Therefore, the share of taxonomy non-eligible activities in our capital expenditures is 97%. Due to our extensive M&A activities, we also report an additional ratio that we adjust for the influence of business acquisitions. In this analysis perspective, the taxonomy-eligible share increases to 5% and now reflects the capital expenditures attributable in 2022 to plants that manufacture the taxonomy-eligible products.

Operational expenditures

In accordance with the Taxonomy Regulation, the ratio’s denominator must cover direct non-capitalized costs that relate to research and development, building renovation measures, short-term leases, maintenance and repair. Any other direct expenditures relating to the day-to-day servicing of assets of property, plant and equipment by the company itself or third parties must also be included.

The share of operational expenditures for taxonomy-eligible products amounted to 8% of the total operating expenditures. Therefore, the share of taxonomy non-eligible operating expenditures is 92%. The share of taxonomy-compliant operating expenses amounts to 0.1% of our operating expenses.

In 2022, our portfolio strategy was again shaped primarily by specific product and application development. We put the needs and expectations of our customers at the center here and frequently pursue projects together with the customers concerned or other high-powered partners.

In 2022, we expanded our Scopeblue series with innovative products.

Scopeblue

Bayferrox

Reusing plastic waste as a raw material is an important element of the circular economy, but requires that the different plastics be separated according to type first. With the new black pigment Bayferrox 303 T from our Inorganic Pigments business unit, we can help to increase the recycling rate for plastic packaging, which is still far too low around the world. The innovative pigment for coloring black plastic reflects 20% of near-infrared radiation (NIR). This enables plastics to be identified efficiently and costeffectively with the aid of NIR detectors like those used for sorting waste.

Lewatit

For us, innovation also means continuously enhancing the applicability of the products we have already established on the market. One example of this is the new type of Lewatit ion exchange resin, with which we open up new areas of application in the electronics industry and microsystems technology. Thanks to an improved polymer matrix in conjunction with a modified formula, we can now manufacture the product to the very highest degree of purity. In the future, Lewatit can therefore be used in the processing of ultra-pure water, which is necessary for semiconductor manufacture.

Adiprene

One of the most challenging applications for polyurethane casting systems is high-temperature applications. As polyurethane chemistries have advanced over the years, casting systems are being used more frequently in this high-performance segment. Our new Adiprene LF TR400 high-temperature prepolymer is much easier to process than comparable prepolymer systems for high-temperature applications. For example, it offers a manageable processing/pour life. The resulting cast elastomers perform better than comparable, established polyurethane high-temperature systems and do not change their properties under heat stress. A further strength is high resistance to heat aging at up to 150 °C.

Emerald NH500

We have developed Emerald NH500 to market maturity as an innovative flame retardant. This new, phosphorus-based product has been specially designed for use in high-performance plastics and electric mobility. It exhibits very good flame-retardant properties in combination with other additives and easily passes the relevant fire safety tests. Versatile formulations ensure that the mechanical properties and other functional characteristics of the end products are maintained. In addition, the additive offers excelent thermal stability and boasts a unique morphology.

Nagardo

Another innovation, our natural preservative Nagardo, has now also been launched in Europe following the U.S., Australia, New Zealand, and Canada. We obtained approval for use in non-alcoholic beverages the EU in the reporting year and continue to expand the global footprint of Nagardo.

European beverage producers can now make use of a long-awaited natural preservative that not only efficiently safeguards product quality but also enables them to transform their product ranges and to meet consumers’ growing demand for natural ingredients.

APAC Application Development Center (AADC)

In order to continue bringing product and application innovations successfully to market, we are enhancing our global network of research and development sites in a targeted manner. Since June 2021, our new APAC Application Development Center (AADC) in Shanghai has brought the research and development activities of the three business units Polymer Additives, Lubricant Additives and Urethane Systems together under one roof. We thus intend to better exploit the growth potential in the Chinese market, the largest chemicals market in the world.

Research and development seal

The Stifterverband has awarded LANXESS the "Innovative through Research" seal for its commitment to research and development. Since 2014, this has recognized research-based companies for the special responsibility they assume for the state and society with the seal.

Freigabe zur Verwendung liegt vor

Freigabe zur Verwendung liegt vorOur customers’ satisfaction is not only an indicator of our success, but above all also a requirement for it. We therefore work continuously on the meaningful and best possible consideration of customers’ constantly changing needs in our product and process innovations. In addition, we aim to build on and consolidate our relationships with our customers.

Our direct interaction with customers resumed in 2022, having been still severely restricted by the coronavirus pandemic in 2021. Customer visits and on-site care were possible again, as were face-to-face events and trade fairs. Overall, a balance has arisen between physical and virtual meetings that makes it possible to conserve resources while simultaneously maintaining all-important personal contact. Successful new formats such as webinars and technical expert sessions were continued. Although personal customer service makes a substantial contribution to our success, virtual cooperation has also proven useful thanks to higher flexibility and reach and better compatibility with customers’ flexible working models, for example.

When forming our customer relationships, the top priorities are customer satisfaction and avoiding customer complaints. Based on a central customer relationship management (CRM) system and a uniform complaint management platform, each of our business units has its own market- and customer-oriented complaint management and optimization processes. Shared elements of these processes include clear targets, for example in relation to the reduction of customer complaints or processing times for customer complaints, as well as a corresponding statistical analysis of the feedback received, and structured monthly reporting to the management of the respective business unit. Various bodies and dialog forums, such as the Marketing & Sales Community that meets quarterly, also guarantee the regular exchange of experiences between our business units and Group functions.

In our digitalization offensive, we use software to improve the speed and efficiency of the communication between our customer service teams and their respective customers. In light of the large number of simultaneous orders, it is a major challenge for our customer service employees to keep track of changes across the entire order acceptance, production and delivery process. Here, we are assisted by software solutions that continuously search our ERP systems for changes in order data records, factor in external information and compare it with dynamic specifications.

Customer satisfaction surveys are essential for LANXESS in order to determine potential for improvement in customer relationships and to check whether customer requirements have changed. LANXESS conducts an anonymous online survey of all relevant customers in all business units once every two years.

In terms of content, the survey aimed to evaluate LANXESS’s performance overall (in comparison to the general competition) and to indicate whether customers would recommend LANXESS. Customers were also asked if they intended to continue the business relationship in the future and to assess the advantages resulting from this relationship.

In the current 2022 survey, the customer retention index (CRI) score was 71 and thus at the same level as our competitors. The score particularly reflects the strained economic situation of the last two pandemic years, the general global supply shortages in procurement, the drastic restrictions in logistics, and the sharply increased raw material and energy prices.

Based on the latest results of the customer satisfaction analysis, we will implement targeted measures at LANXESS and in the business units in order to remain a reliable and value-enhancing partner for our customers and thus to keep successfully retaining them in the long term.